Vi har ett flertal olika typer av automatiserade lösningar som vi erbjuder våra kunder. Våra olika siter har olika inriktningar på vilka flöden som passar bäst. Det är också därför som våra olika siter har olika uppsättningar av automation. Vår bredd av automation innebär också att vi kan placera våra kunders varor där de passar bäst och inte tvinga in dem i en automationslösning som inte alls passar verksamheten.

Vi delar in våra automationer i fyra kategorier:

- Plock

- Pack

- Sortering

- Intelligent kringautomation

Plock

Att plocka varor styrs först av vad det är för typ av order och därefter av vilka varor det är. Baserat på detta hanterar vi ordrar på olika sätt. Det är väldigt vanligt att en kund hos oss nyttjar flera olika plocksätt, allt för att optimera sitt flöde.

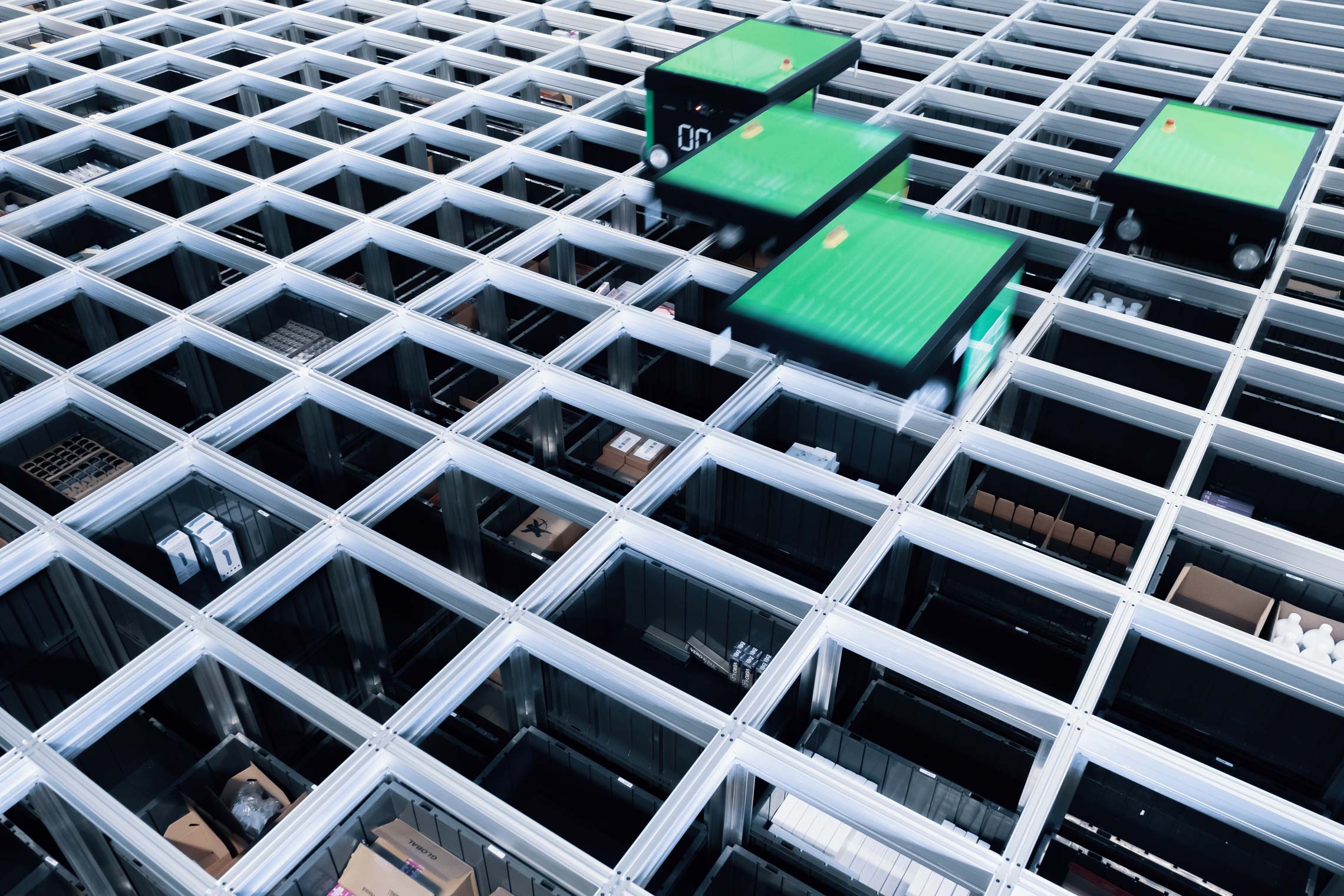

Autostore

Autostore är en automationslösning som använder sig av en innovativ robotik för att hantera lagerhållning. Autostore har många fördelar, inklusive hög hastighet, hög kapacitet och stor flexibilitet. Automatiseringen gör det möjligt att hantera stora volymer av varor och minska den manuella arbetsinsatsen. Eftersom Autostore kan hantera både små och stora föremål, kan den användas i många olika branscher.

KNAPP Shuttle OSR

Vår shuttle-lösning är den mest avancerade automationen vi har. Här kombinerar vi lagerhållning, plock och delvis paketering i ett. Systemet håller tusentals backar som i sin tur är uppdelade i lagerplatser där vi lagerför kundernas varor. När det kommer in en order skickas rätt back fram till en plockstation där varor plockas ut för vidare transport till paketering. Med detta system kommer man upp till runt 500 orderader per station och timme. För att klargöra: 500 orderrader är oerhört snabbt!

Roboplock

Med hjälp av vårt eget WMS i kombination av egenutvecklade Roboplocks (handscanners) kan vi själva styra plockrundor, singelplock, multiplock, DiPa, batchplock och mycket mer. Vi gör det manuella plocket mer automatiserat och mer digitalt och får på så sätt ett oerhört effektivt flöde. Ofta kan vi med hjälp av Roboplock komma upp i högre output än både Autostore och Shuttle-lösningar.

Vertical Lifts

Tillsammans med vår leverantör har vi tagit fram en kombination av system som tillsammans blivit riktigt effektiva. Här plockas varor där backar kommer till plockstationer och med hjälp av pick-to-light plockar man varorna. Avgörande för om vi väljer att använda denna metoden är vilken typ av produkter som vår kund har samt SKU-struktur och lagersammansättning.

KNAPP Flowrack

Ett system av conveyerbanor där det automatiskt skjuts ut plockbackar för respektive order. Backarna går sedan runt i ett slutet system, stannar i de zoner där plock ska ske och med pick-by-light styrs plocket. Efter komplett plock går orderbaken tillbaka till ursprungsläget där automatiserad eller manuell paketering sker. Anläggningen passar kunder med färre SKU´n men där man har högt orderflöde.

Pack

För paketering har vi en rad olika lösningar som anpassas efter våra kunders behov. Allt ifrån små effektiva lösningar till den största maskinen som är över 40 meter lång där samtliga ordrar 3D-scannas och emballage skapas i realtid. Kombinationen av lösningar är det som är avgörande och även här är det vanligt att en kund nyttjar olika paketeringsmöjligheter.

Rekordet för antal packade ordrar var under Black Friday där kombinationen av våra lösningar gjorde att vi paketerade en order per sekund.

Här är några exempel på våra automationer för paketering:

B+

Autobag

Carton Wrap

Semiautomatiserade packlinor

Påspackmaskiner

Lådförslutare

Sortering

Automatiserad sortering är en viktig del av flödet. Genom att använda sorteringsmaskiner och digitala lösningar för att sortera ordrar kan vi öka hastigheten och effektiviteten på våra siter. Detta samtidigt som vi minskar fel och behovet av manuell hantering.

Fördelar med automatiserad sortering inkluderar en snabbare hantering av stora volymer av paket, minskad personalnärvaro och lägre risk för arbetsrelaterade skador, mer exakt sortering och mindre felaktig leverans, och ökad spårbarhet och säkerhet för leveranser. Dessutom kan vi tillgodose våra kunder mer intressant data som kan hjälpa deras affär.

Utöver sortering arbetar vi mycket med adressering och då menar vi inte själva etiketten eller att labla utan mycket mer. Vårt WMS tillsammans med information från våra kunders ERP, e-handelsplattformar eller andra system styr vilken transportör som ska nyttjas. Vårt WMS hanterar all TA och med hjälp av automatiserad adressering ser vi till att våra kunder kan nyttja alla våra transportavtal. Utöver informationen från system kan vi även styra valet av transportbolag baserat på värde, vikt, volym, kolli, mottagare, land, tull och mycket mer.

Intelligent kringautomation

Inom denna kategori kommer all automation som vi integrerar mot vårt WMS och system. Det kan vara specielle kundflöden, flöden med högre krav som måste ha speciell hantering, semiautomatiserade effektiviseringar och mycket annat som vi utvecklar själva. Ett för att vi kan, två för att vi är bra på det och tre: det hjälper våra kunder.